Testing at 9Six9 Wheels

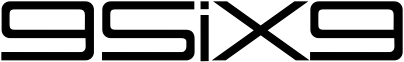

Finite Element Analysis

We use 20+ years of wheel load FEA data to simulate different conditions and its effect on the wheel design, to see how to fine tune the design detail to maximize the final wheel strength.

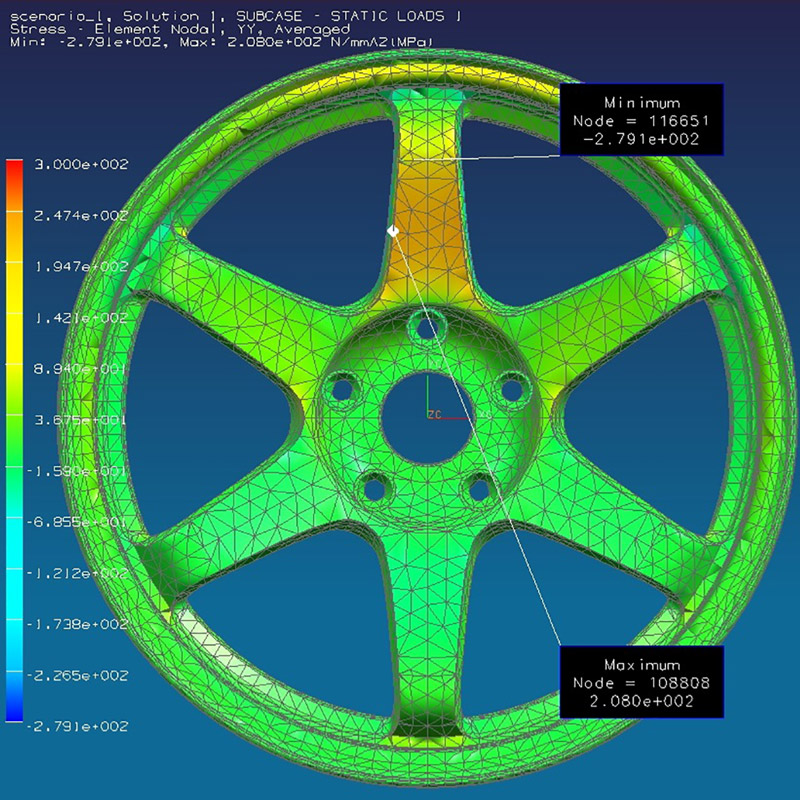

Coordinate Measuring Check

We use CMM to check the initial wheels, production wheels, and end pieces. To make sure the wheel we develope and produce are consistent.

Tensil Test

At each production run. We take pieces out from the wheel to check the material strength and level of stress to make sure the material in the wheel meet all the requirement.

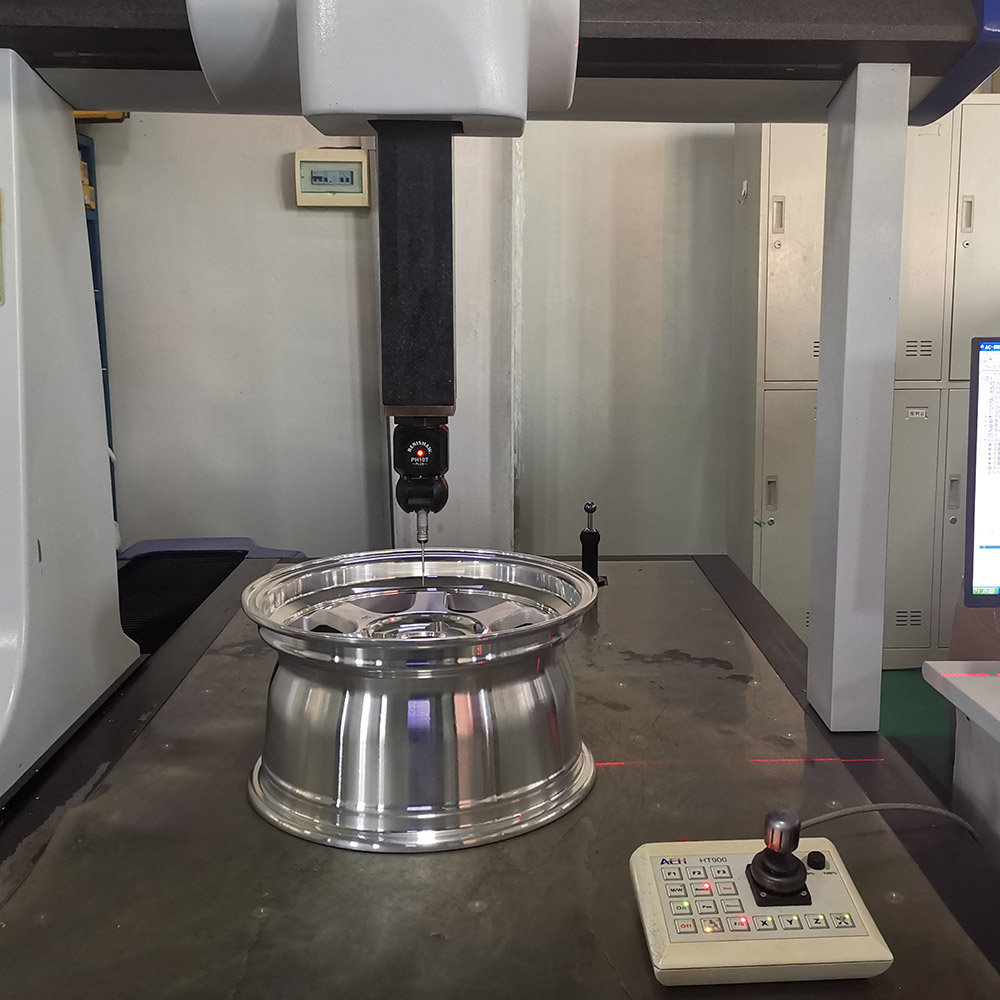

X-Ray Check

To ensure there are no porosity in the wheel. We use a X-Ray machine that is build-in to our production line to check inside of each wheel.

Hardness Check

Aluminum wheel go through many heat cycles. We check hardness to make sure wheels has been properly heat-treated.

Radial Fatigue Test

We test the development wheels and production wheels on simulate road condition. Under dynamic load for millions and millions of cycles.

Impact Test

We test the development wheels and production wheels to simulate axial curb impact collision properties of the wheels.

Bending Fatigue Test

We test the development wheels and production wheels to simulate dynamic bending fatigue to prolong stress with emphasis on bolt pattern, center bore, and spoke. resilience.

Deformation Test

To check the strength of the inboard rim against bad road condition. Inboard rim is the first impact point from the uneven road surface due to the vehicle suspension negative offset.

Vibration Test

To ensure our wheels and caps can sustain the vibrations.

Accelerated Weather Test

Test the paint performance by using acclerated weathering test to simulated long term exposure to outdoor conditions, UV, wind, ice, sand, and dust.

Corrosion Test

We test corrosion to evaluate performance of wheel, cap matera,l and coating. To make sure our wheels can withstand long term capability under harsh conditions.

Chipping Resistance Test

To determine the resistance of painted surface on wheels that have been impacted by gravel.

Helium Leak Test

Each wheel is leak-proof checked by using the smallest gas molecule to ensure accuracy.

Runout and Balance Check

We check each wheel for balance and run-out before packaging. Our fully automated run-out and balance machine check radial run-out, lateral run-out, static balance, and dynamic balance.